FOLIANT Taurus 760 NG

The FOLIANT Taurus 760 NG is a next generation of popular SF version. It is very compact and fast industrial laminating machine, constructed for non-stop work. It is equipped with a suction feeder, high speed bump separator and options like pallet stacker or Foiler. Due to its format and performance the machine is suitable for all jobs – all kinds of digital printed sheets lamination and high volumes of offset printed sheets size B1+ lamination too. The machine maximum speed is up to 30 m/min., while performance is up to 1800 sheets per hour of B1 portrait (white paper 200 gsm).

Feeder

The FOLIANT Taurus 760 NG is equipped with a rising pile back separation stream feeder and with a suction feed head. It is driven by an Omron servo motor and controlled by a machine central PLC. The Becker vacuum pump is used for sheets back airing. The overlaps are electronically controlled, in an „in-run“ automatic mode, from the touch screen. The accuracy is +/- 2 mm under-lap (in a constant speed). The standard feeder is fitted with a lifting plate and its capacity is a 40 cm pile of paper.

Laminator

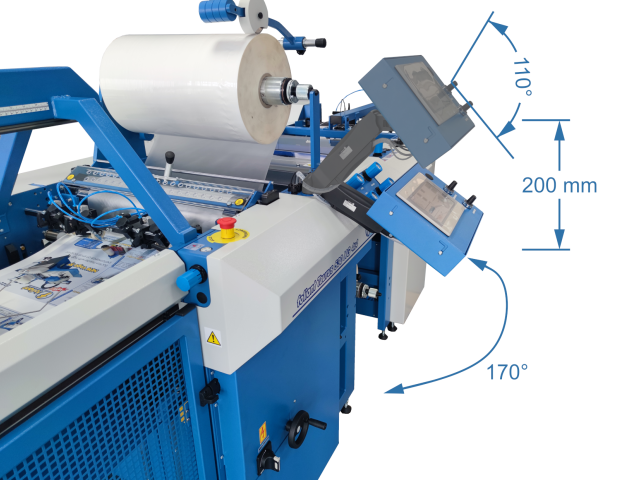

The FOLIANT Taurus 760 NG laminator maximum sheet size is 76 x 110 cm. The minimum sheet size is 32 x 25 cm (A4).The FOLIANT Taurus 760 NG machine is a single sided thermal industrial laminator, laminating the 115 – 600 gsm paper, with an unique „U“ cross bar for perfect lamination of thin sensitive sheets. The laminating unit is equipped with twin decurl unit adjustable during run:

- With a decurl blade for strong de-curling effect. The intensity is adjusted by the angle of the blade.

- With a decurl roller for weaker effect. The back print is protected during the de-curling because the paper it not rubbing against the roller but it is rotating together with it.

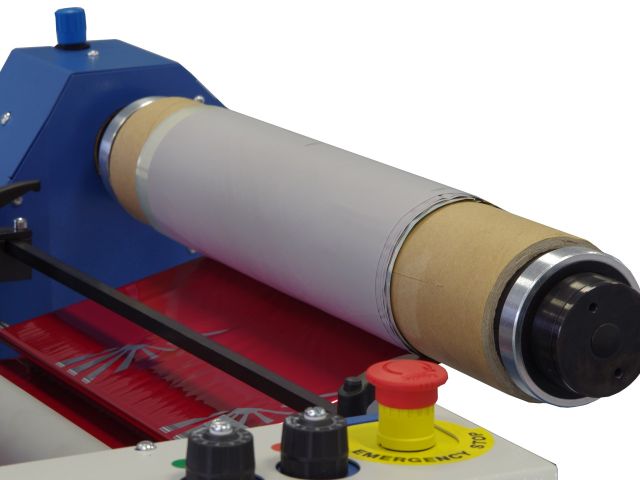

The roll of a film is mounted on an air shaft that allows very convenient, easy and precise film positioning. The shaft capacity is up to 3000 m of the 24 - 31 microns film. The film holder unit is equipped with a trim slitter and a perforating wheel. The laminating process is made between two laminating rollers - a highly polished chrome roller, and a lower hard rubber pressure roller. The laminating roller is heated with a dry electric system inside the roller which consists of several rings mounted directly to inner wall of the roller. This ensures that heat transfer is perfect even at maximum speed. A sensitive temperature sensor is also inside the roller as close to surface as possible. The warming up time is shorter than 10 minutes. The pressure is pneumatically adjustable, with an extra independent control knob for each roller edge.

Separator

The integrated bump separator (sheeter) is equipped with a pair of fast cycling rollers. The process is controlled from the machine PLC unit. The separated sheets are delivered into a vibrating jogger (optional) or a pallet stacker (optional).

Laminating films

The machine laminates the BOPP films (24 – 42 μm) and Nylon films (24 – 35 μm). The PET films (20 – 26 μm) can be laminated with the optional module only.

Safety Measurements

FOLIANT Taurus 760NG is certified by independent testing laboratory DGUV Test and obtained GS mark ("Tested Safety"). The measurements for operators safety are better then required by law in order to minimize injuries.

| Parameter | Value |

|---|---|

Maximal Speed | single side 30 m/min |

Feeding System | automatic, Suction Feeder Foliant, Feeder's Capacity 40 cm |

Overlaps | Automatic, PLC Controlled, Overlaps Accuracy ± 2 mm |

Separation | Automatic, bump rollers |

Paper Weight | 115–600 g/m² |

Main Roller Pressure System | Pneumatic |

Compressor | External, 150 l / min, 6-8 bar |

Minimal Sheets Size (w×l) | 32×25 cm |

Maximal Sheets Size (w×l) | 76×110 cm |

Maximal Performance | 1800 B1 / hour |

Temperature Control | 80–140 °C, Warming Up Time 8 min |

Power Supply | 3 f., 400V AC, 50-60 Hz |

Power | 7950 W |

Mechanical Parameters | Floorspace (w×l) 140×330 cm, Weight: 820 kg |

Modular Stand | |

Pallet Stacker | Semiautomatic Stacker Capacity 73 cm |

Non-sticky pressure roller | |

Air Shaft | Standard |