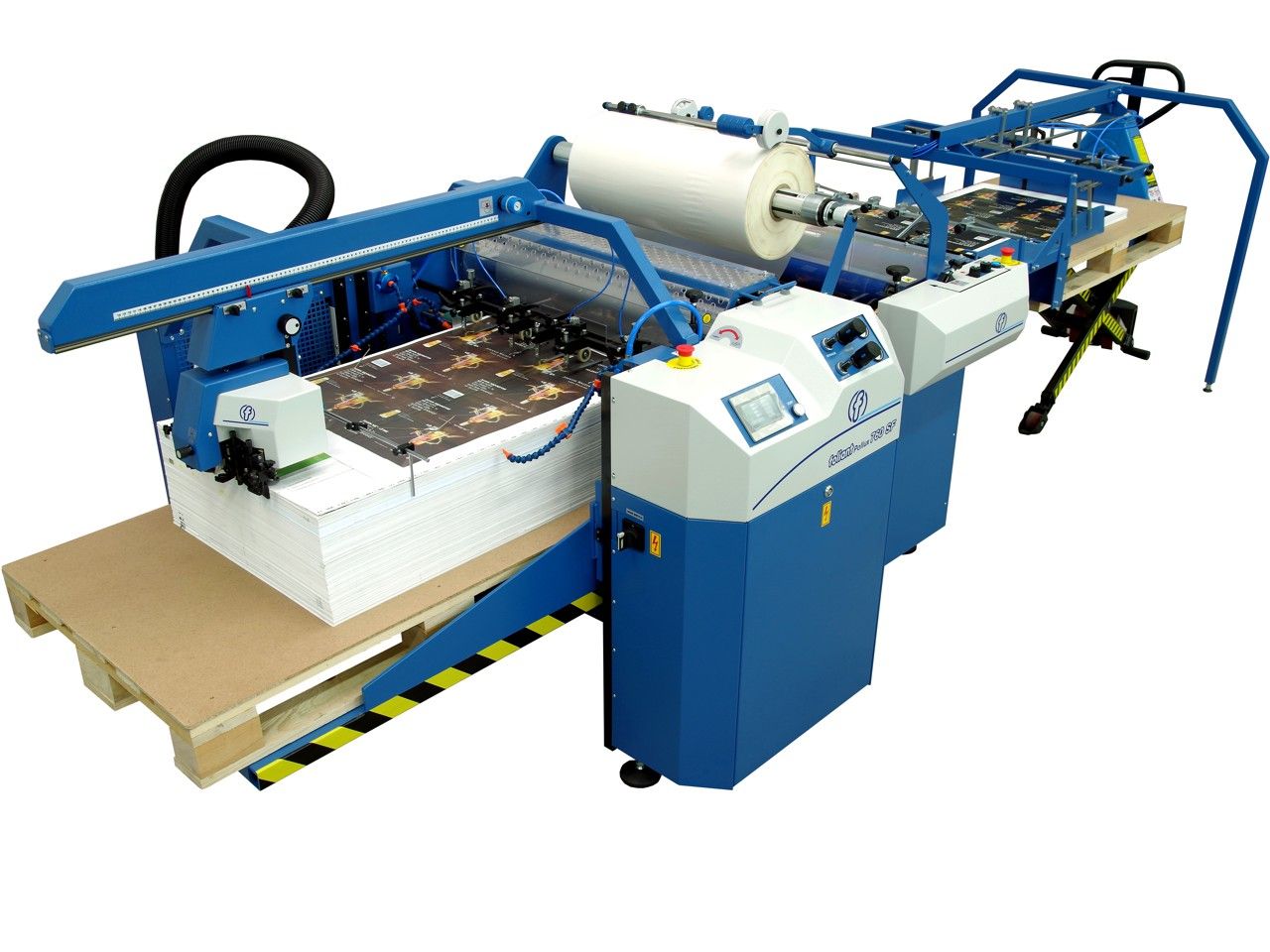

FOLIANT Pollux 760 NG

The FOLIANT Pollux 760 SF is a high speed compact industrial laminating machine, a heavy duty construction machine with a suction feeder and a high speed bump separator, with a walk-in service section and with an optional pallet feeder, a pallet stacker and an electric film loader/manipulator. The machines maximum speed is up to 50 m/min., while the maximum performance is 3000 sheets per hour of a B1 portrait or 6000 sheets per hour of B2 landscape (white paper 200 gsm). The machine requires and external compressor (6 - 8 bar, 150 l / min) as a source of pressured air for its pneumatic systems.

Feeder

The FOLIANT Pollux 760 SF is equipped with a rising pile back separation stream feeder, with a suction feed head. It is driven by an Omron servo motor and controlled by a machine central PLC. The built-in Becker vacuum pump is used for sheets back and sides airing and feeding head suction cups vacuum. The overlaps are electronically controlled, in an „in-run“ automatic mode, from the touch screen. The accuracy is +/- 2 mm under-lap (in a constant speed). The standard feeder is fitted with a lifting plate and its capacity is a 55 cm pile of paper.

Laminator

The FOLIANT Pollux 760 SF laminator maximum sheet size is 76 x 110 cm. The minimum sheet size is 32 x 25 cm (A4). FOLIANT Pollux 760 SF machine is a single sided thermal industrial laminator, laminating the paper 115 – 600 gsm, with an unique „U“ cross bar for the thin sheets flat and safety high pressure lamination, mounted in the front of the main laminating rollers, with an „In run“ adjustable de-curl bar.

The roll of a film is mounted on an air shaft that allows very convenient, easy and precise film positioning. The shaft capacity is up to 3000 m of the 24 - 31 microns film. The film holder unit is equipped with a trim slitter and a perforating wheel.

The laminating process is done between two laminating rollers - a highly polished chrome roller, and a lower hard rubber pressure roller. The laminating roller is heated with 6 contact electric heaters inside the roller, with a sensitive in-roll temperature sensor. The pressure is pneumatically adjustable, with an extra independent control knob for each roller edge. The pressure of pulling rollers is controlled with a pneumatic control knob. There is a service „walk-in“ section between the machine laminating rollers and pulling rollers for an easy machine maintenance and rollers cleaning. The machine requires an external source of pressured air 200 l / min, 6 – 8 bars.

The machine is fitted with OMRON Programmable Logic Controllers, which controls all machines’ functions. Used PLC system includes many automatic items for an easy machine control and a reliable lamination. The whole machine is controlled by an interactive easy understandable icon based touch screen – no language mutation is needed.

Separator

The integrated bump separator (sheeter) is equipped with a pair of fast cycling rollers. The process is controlled from the machine PLC unit. The separated sheets are delivered through a high speed belt conveyor (for safety loading to the reception unit) into a vibrating jogger (optional) or a pallet stacker (optional).

Lamination Films

The machine laminates the BOPP films (23 – 42 microns), Nylon films (max 35 microns) and PET films (max. 25 microns).

| Parameter | Value |

|---|---|

Maximal Speed | single side 50 m/min |

Feeding System | automatic, Suction Feeder Foliant, Feeder's Capacity 55 cm |

Overlaps | Automatic, PLC Controlled, Overlaps Accuracy ± 2 mm |

Separation | Automatic, bump rollers |

Paper Weight | 115–600 g/m² |

Main Roller Pressure System | Pneumatic |

Compressor | External, 200 l / min, 6-8 bar |

Minimal Sheets Size (w×l) | 32×25 cm |

Maximal Sheets Size (w×l) | 76×110 cm |

Maximal Performance | 3000 B1 / hod. |

Temperature Control | 80–140 °C, Warming Up Time 8 min |

Power Supply | 3 f., 400V AC, 50-60 Hz |

Power | 12000 W |

Mechanical Parameters | Floorspace (w×l) 165×395 cm, Weight: 990 kg |

Modular Stand | |

Pallet Stacker | Semiautomatic Stacker Capacity 73 cm |

Non-sticky pressure roller | |

Air Shaft |