FOLIANT Gemini 400 NG-T

The FOLIANT Gemini 400 NG-T is a next generation of high pressure laminating machine developed for a digital printing machines outputs lamination. The machine is equipped with a pneumatic system of laminating rollers pressure with an easy thrust control. A small compressor is integrated inside the machine frame. The machine has been designed with an operating width of 380 mm and it represents an ideal choice for professional single side lamination in digital shops and all other printing shops, printing and processing sheets up to B3+ size (the length of laminated sheets is not limited, in practice lamination it is ~70 cm). Maximum speed is up to 15 meters/min.

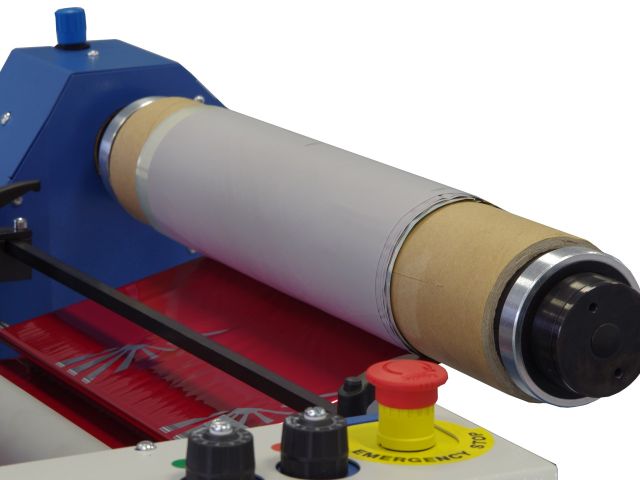

Laminator

The FOLIANT Gemini 400 NG-T laminator maximum sheet size is 38 x 66 cm. The minimum sheet size is 30 x 25 cm (A4). The roll of a film is mounted on an easy handle shaft with a film tension control breaker. The shaft capacity is up to 3000 m of 24 - 31 microns film. The film holder unit is equipped with a trim slitter and a perforating wheel. The laminating process is done between two laminating rollers - a highly polished chrome roller, and a lower hard rubber pressure roller. The laminating roller is heated with an infra-red heating spiral, with a sensitive contact temperature sensor. The pressure is pneumatically adjustable to achieve an extra high pressure between the laminating rollers. A small compressor is integrated inside the machine frame.

The laminating unit is equipped with an adjustable twin decurl unit:

- With a decurl blade for offset printed sheets decurling

- With a decurl roller for digital printed sheets decurling (to prevent scratches on sheets printed on both sides by digital print with sensitive inks).

Feeding

The FOLIANT Gemini 400 NG-T is a manual machine. The feeding is manual. The laminating unit equipped with a synchronized feeding conveyor and an adjustable side guider for an easy loading.

Separation

The FOLIANT Gemini 400 NG-T is a manual machine. The separation is manual. Due to the perforation of film (done in the process of laminating) the whole process is easy.

Automatic Separation (Upgrade)

Any time later the machine can be upgraded with an automatic separator. The belt separator (sheeter) is equipped with a separating roller and a deflection wheel. The separated sheets are delivered into a reception unit or a vibrating jogger (options). More information is available at FOLIANT Gemini 400 NG-S.

Laminating Films

The machine laminates the BOPP films (23 – 42 microns) and Nylon films (max. 35 microns). Film rolls with core diameter 3" and 1" can be used.

| Parameter | Value |

|---|---|

Maximal Speed | single side 15 m/min |

Feeding System | Manual |

Overlaps | |

Separation | Manual |

Paper Weight | 115–350 g/m² |

Main Roller Pressure System | Pneumatic |

Compressor | Included |

Minimal Sheets Size (w×l) | 20×30 cm |

Maximal Sheets Size (w×l) | 38x72 cm |

Maximal Performance | 1200 B3 / hod. |

Temperature Control | 80–140 °C, Warming Up Time 5 min |

Power Supply | 230 V AC, 50-60 Hz |

Power | 2550 W |

Mechanical Parameters | Floorspace (w×l) 74×117 cm, Weight: 152 kg |

Modular Stand | Standard |

Pallet Stacker | |

Non-sticky pressure roller | |

Air Shaft |